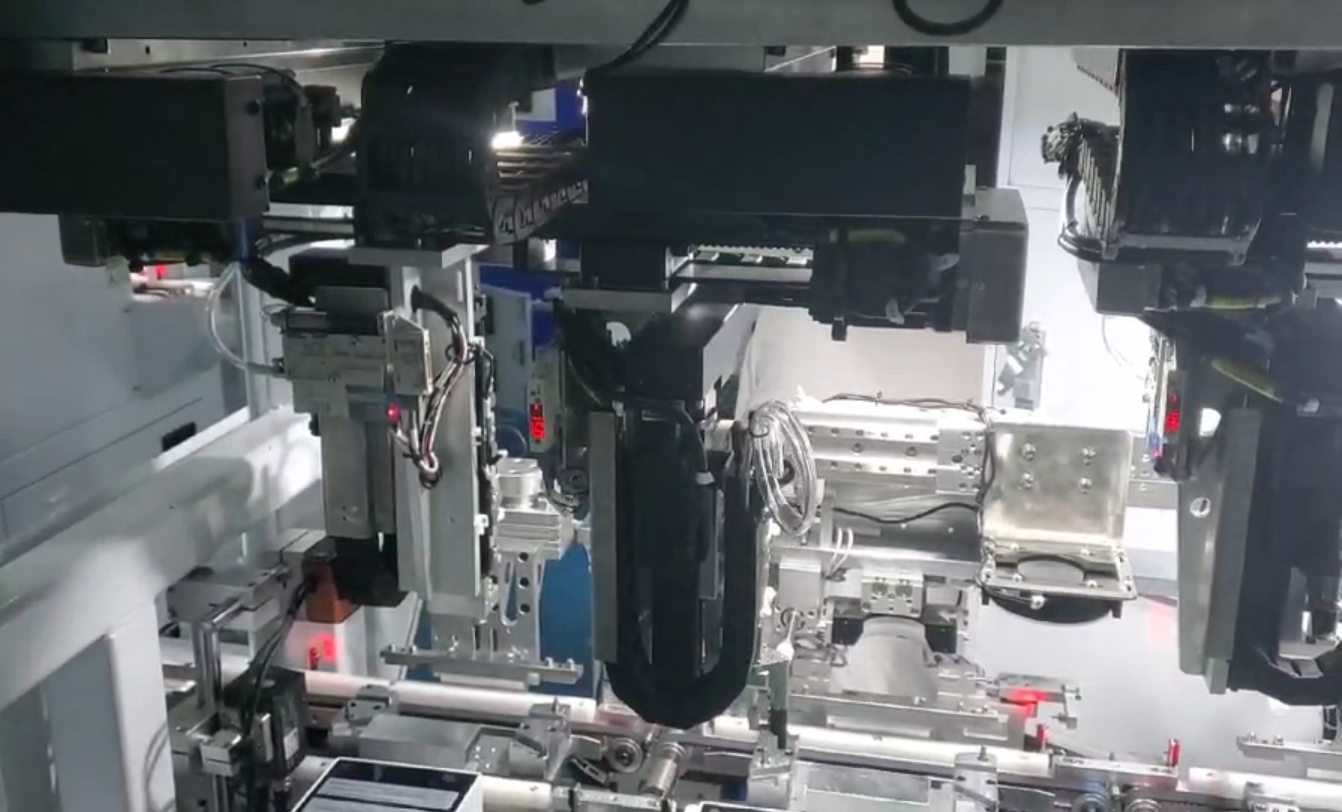

Screw machine positioning guide system

The Boming screw machine positioning system analyzes products requiring fastening by taking photos. After identifying the screw holes, it uses visual positioning and correction to establish the relationship between the screws and holes, guiding a multi-axis robot to the specified coordinates to automatically complete the screw fastening process. Products can be efficiently changed simply by modifying the positioning points.

Core Advantages

Intelligent

Integrates multiple technologies, powerful hardware and software

(Complete range of standard and customized products)

Advanced Algorithm

Deep Learning defect detection algorithm, model reasoning (defect segmentation or defect location)

(Background interference removal, defect merging, detected defect screening, etc.)

One-button Start

One-button start detection, multiple cameras work independently

(Numbering and summarizing the detection results)

Automation

Automatic detection, products flow out with the conveyor line, no manual selection required

(Detection workstations are optional)

High Precision

High dimensional detection accuracy, fast speed, high detection efficiency

(Repeatability: ±5μm)

Developments are Customizable

Custom development can be carried out according to actual needs,

(Custom Development)

Vision Solution

Industry-customized solutions

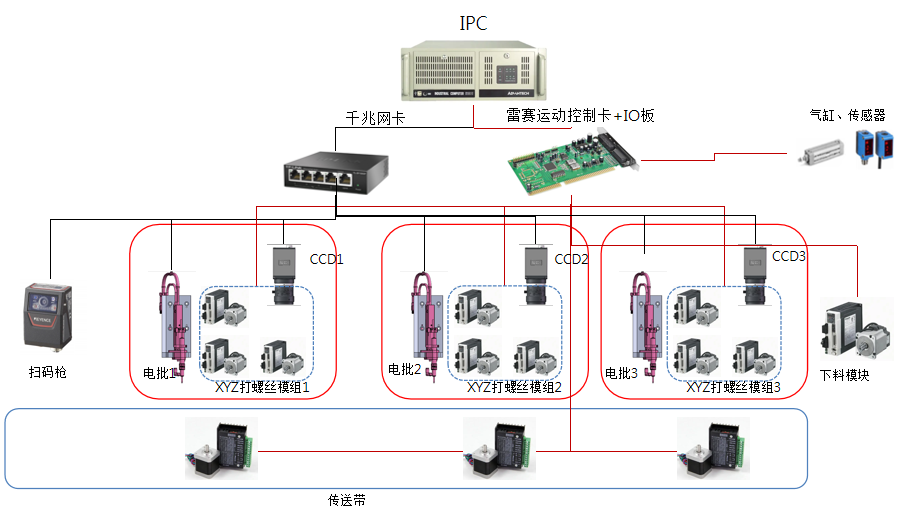

Screw Assembly Visual Positioning Software

• Data statistics function, assembly yield statistics, Excel reports, Mes communication.

• Image storage, saved by date, shift, and product type, with regular deletion function.

• Motion control:

Motion parameters can be set

Manual control is possible

Add automatic functions

• Visual positioning algorithm is used.

Application Scenarios

Applied to provide fruit customers with a new generation of cowling assembly screw locking products, deeply solving industry pain points, and is your optimal choice.