Magnetic material appearance size sorter

The Boming magnetic material appearance size sorting equipment uses deep learning to enhance feature extraction, maintaining a strong defect detection capability even when defect features are not obvious. It also uses traditional image processing to extract defect characteristics, allowing it to more closely meet customer-defined judgment conditions, providing quantitative judgment and enabling quick modification of judgment conditions. The operation is simple and clear; with a single-button start, it performs comprehensive detection of defects such as size, chipped corners, hidden cracks, and poor plating on the magnetic materials.

Core Advantages

Intelligence

Integrates multiple technologies, powerful hardware and software

(Complete range of standard and customized products)

Advanced Algorithms

Deep Learning defect detection algorithm, model inference (defect segmentation or defect location)

(Background interference removal, defect merging, detected defect screening, etc.)

One-Click Startup

One-click detection startup, multiple cameras work independently

(Numbering summary sends detection results)

Automation

Automatic detection, products flow out with the conveyor line, no manual selection required

(Detection workstation optional)

High Precision

High dimensional measurement accuracy, fast speed, high detection efficiency

(Repeat detection accuracy: ±5μm)

Customizable Development

Customizable development according to actual needs,

(Customized Development)

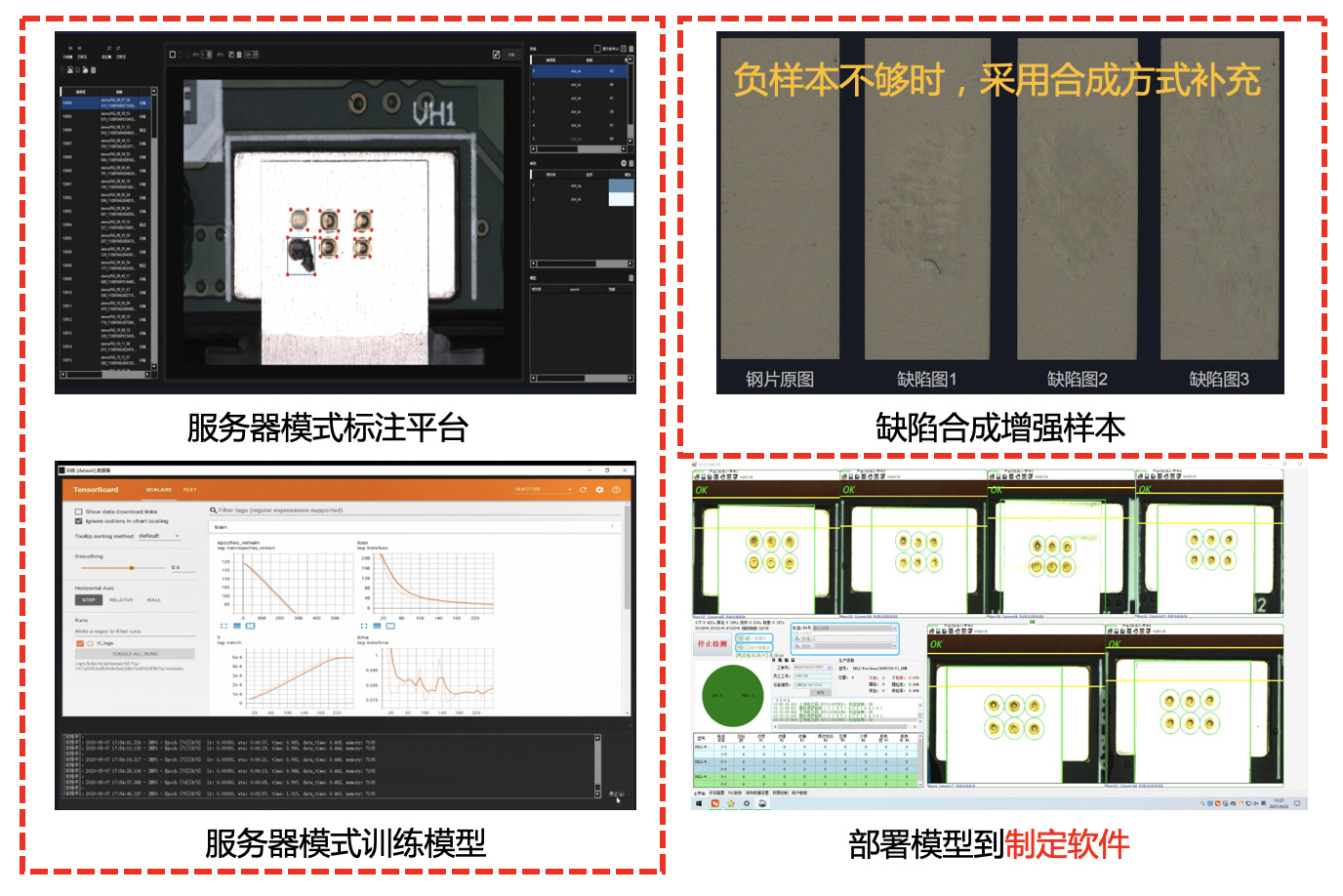

Vision Solution

High intelligence

Software Solution

· Based on the existing turntable machine general software, customized modifications are made specifically for this magnet.

Different camera modules are assigned according to different detection vision or detection items.

· One-click detection startup, multiple cameras work independently, and the number summary sends detection results.

· Compatible with traditional version and deep version detection algorithms.

· Provides a defect type detection whitelist function to selectively detect different defects.

· Provides multi-level access control to ensure the encryption of software parameter modifications.

Algorithm Solution

Dimensional detection uses traditional measurement algorithms

Traditional image processing method preprocessing

Target validity determination

Background interference removal

Feature enhancement

Dimensional transformation

· Defect detection algorithm uses traditional image processing algorithm and deep learning defect detection algorithm

Deep Learning defect detection algorithm

Model inference (defect segmentation or defect location)

Self-developed customized algorithm

The detection workstation is optional and can be configured according to actual needs. The equipment size will vary with different configurations.

Defect Detection Effect

The detection workstation is optional and can be configured according to actual needs. The equipment size will vary with different configurations.

Solution Parameters

Equipment size (L*W*H)

2660*1400*1800mm

Detection product size

Length: 15-55mm Width: 4-30mm Thickness: 0.5-5mm

Detection product shape

Squares, tiles

Detection product plating

Nickel plating, black epoxy

Dimensional detection items

Length, width, thickness, parallelism, perpendicularity, R angle

Dimensional detection accuracy

Repeat detection accuracy: ±5μm

Appearance defect detection items

Mechanical defects: missing corners, hidden cracks, warping, internal cracks, knife marks

Plating defects: particles, shrinkage, delamination, watermark, fluff

Minimum detectable size of appearance defects

Length * width: 0.06 * 0.06mm

Magnetic direction

Detects the magnetic direction, the miss rate is 0, optional

Detection efficiency

100-200pcs/min