Lithium battery industry solutions

The Boming serpentine wave electrode detection equipment and lug weld height detection equipment are tailored for the lithium battery industry. Working with well-known lithium battery companies, we deeply address industry pain points. We provide professional detection of the post-welding height of lithium battery lug welding processes, as well as detection of serpentine and wave defects in lithium battery electrodes. Repeatability accuracy reaches the micrometer level.

Core Advantages

Intelligent

Integrates multiple technologies, powerful hardware and software

(Complete range of standard and customized products)

Advanced Algorithms

Deep Learning defect detection algorithm, model inference (defect segmentation or defect location)

(Background interference removal, defect merging, detected defect screening, etc.)

One-Click Start

One-click start detection, multiple cameras work independently

(Numbered summary of detection results sent)

Automation

Automatic detection, products flow out with the conveyor line, no manual selection required

(Detection workstation optional)

High Precision

High dimensional measurement accuracy, fast speed, high detection efficiency

(Repeat detection accuracy: ±5μm)

Customizable Development

Customizable development according to actual needs,

(Custom Development)

Vision Solutions

Industry-customized solutions

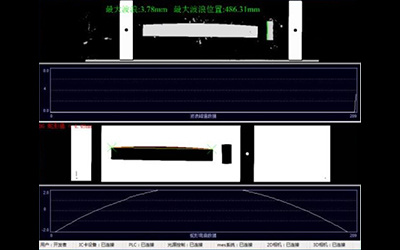

Serpentine Wave Tab Detection

Professional detection of serpentine and wave defects in lithium battery tabs

· At present, most lithium battery manufacturers manually measure serpentine and wave shapes, resulting in low measurement accuracy and efficiency. Therefore, Boming Vision has launched a dedicated device for testing the serpentine and wave shapes of tabs, This device is an offline measurement device.

Compatible with tabs of length 168~1300mm and width 13.5~152mm, with a repeat measurement accuracy of 0.1mm.

Compatible with continuous coating, intermittent coating, and zebra coating types of tabs, suitable for the consumer electronics battery industry.

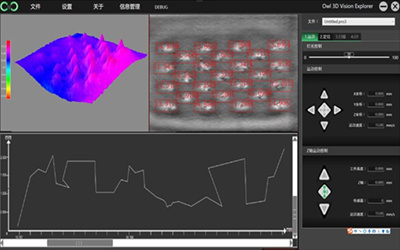

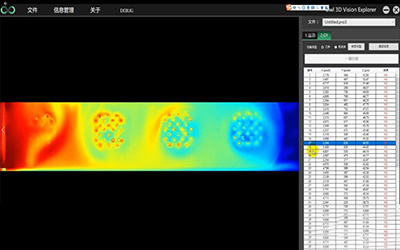

Tab Weld Height Detection

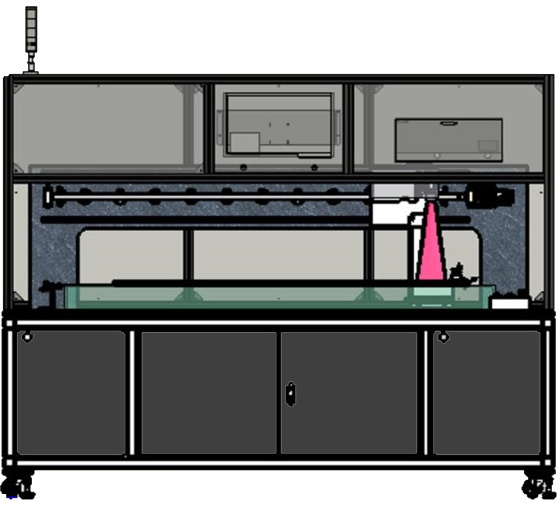

Boming Vision 3D General Detection Platform

Option to only display the location and value of out-of-tolerance solder points.

Wizard-style operation, simple and convenient.

Commonly used in lithium battery surface packaging processes.

Industry-Specific Equipment

Boming's serpentine wave tab detection equipment and tab weld height detection equipment are tailor-made for the lithium battery industry, working with well-known lithium battery companies to solve industry pain points and are your best choice.

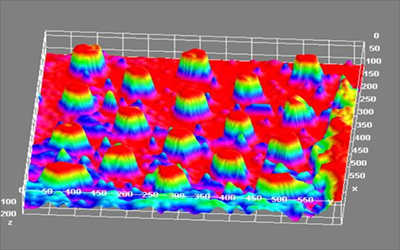

Visual Inspection Results

3D general detection platform, accurately detects the height of solder point protrusions of tab welds and displays the 3D image of the weld area