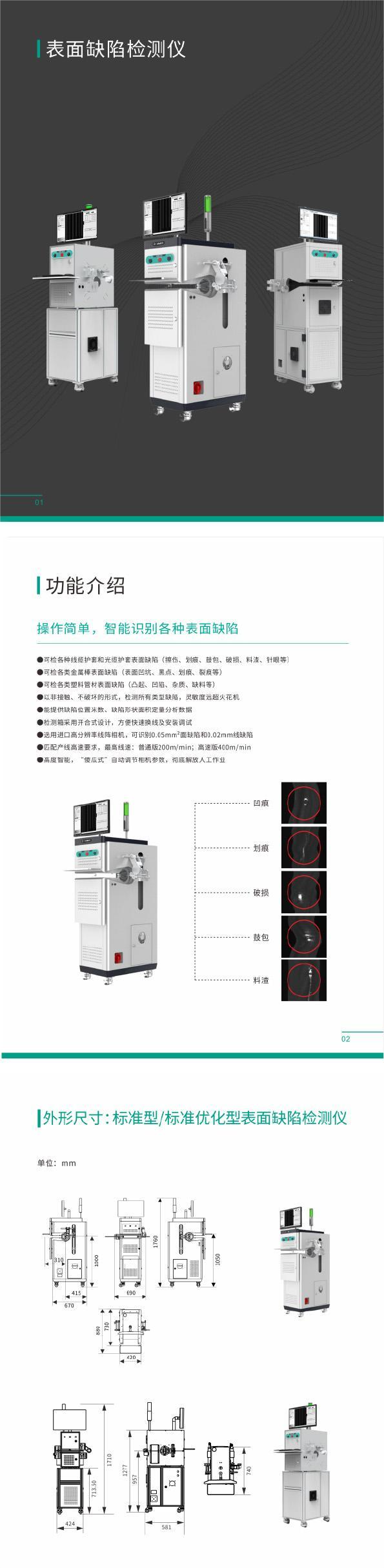

Customized surface defect detector

Subclassification

Keyword

Product Characteristics

1. Real-time online monitoring of quality anomalies replaces manual re-inspection, reducing redundant processes;

2. High-speed line scan cameras are used, with a maximum matching speed of 180m/min, which is the basis for achieving high-speed production and indirectly increases output;

3. The machine can act as a terminal to upload data to a central server or allow data to be read by MES systems, etc.;

4. It can act as a server for other detection equipment (such as roughness meters, diameter measuring instruments, etc.) for data storage and visual display;

5. It can be used with our company's defect marking module to assist in locating defects and improving repair speed;

6. AI algorithm software can be optionally installed to achieve automatic defect classification;

7. Flexible optical environment, compatible with a variety of products.

Functional Scope:

1. Diameter change monitoring;

2. Outer sheath surface defect detection;

3. Data query, traceability, and quality reporting;

4. Alarm prompts;

5. Backend communication with roughness meters, diameter measuring instruments, and inkjet printers;

6. Visualization of quality anomalies.

Product Details

Product and service quality have received high praise from customers.

Key words:

Other Products

undefined

Need service or support? Welcome to enable the online message function, we will be timely feedback and provide you with appropriate solutions.