Guangdong 3D profile measuring instrument is based on CCD digital image

Release Time:

2022-09-09 09:03

Guangdong 3D profile measuring instrument is based on CCD digital image, and is produced by relying on computer screen measurement technology and powerful software ability of spatial geometric calculation. After the computer is installed with a special control and graphic measurement software, it becomes a measurement brain with a software soul and is the main body of the entire device. It can quickly read the displacement value of the optical ruler, and obtain the result immediately through the operation of the software module based on spatial geometry; and generate a graph on the screen, and the operator can compare the graph, so that the possible deviation of the measurement can be visually distinguished. Guangdong 3D contour measuring instrument is a high-precision optical Guangdong 3D contour measuring instrument. It is composed of a high-precision workbench structure.

The software explains the measurement.

Measure complete geometric dimensions (points, lines, surfaces, circles, spheres, cylinders, arcs, cones), shape and position tolerances (line, plane, true circle, true sphere, cylindricity, position, parallel, perpendicular) .

When the power is turned off abnormally, the software can automatically restore the data to prevent the measured data that affects the work efficiency from being restored.

Provide powerful linear and nonlinear compensation functions to ensure higher machine accuracy.

Various styles of EXCEL and WORD editing can be transferred, and tolerance levels can be set, and OK and NG can be judged immediately.

A good tool for CAD reverse engineering is the measurement graphics and clear annotations; and it can save IGES and DXF file formats.

Realize a large number of automatic detection, improve work efficiency, such as programming self-learning, array replication and other functions.

The super image of the deburring function can avoid overlapping and breaking of line segments.

A variety of ways to move support mouse, keyboard, screen, joystick, etc., more convenient to find the measurement object.

Quick positioning in the measured area (element area, drawing area, digital area, picture navigation, etc.).

The super image of the deburring function can avoid overlapping and breaking of line segments.

There are many methods for the image edge finding tool, and the element measurement method is simpler and more accurate.

Through the global scanning function, it can be quickly changed to the global scanning function of CAD format to realize fast reverse engineering copying.

Network version measurement function Network version workpiece image line measurement: directly select the approximate position of the line segment on the edge to be scanned. The software can automatically analyze the edges of objects in the web version and make line measurements.

(Optional) CAD comparison offline programming module

1. Shorten the time of editing the program, you can load the DXF file and directly convert it into a measurement program.

2. It can work offline (another PC operation) without affecting the normal operation of the machine.

3. Using the workpiece that needs to measure large size, it can enter the automatic measurement conveniently and quickly, saving the measurement time.

Touch probe module (optional): supports complete 3D measurement, and can realize image@probe common center measurement and automatic measurement after programming.

Non-contact laser module (optional): Detect the flatness and height of the workpiece, such as a narrow workpiece area, and specify the measurement position through the image.

Latest News

2022-09-09

3D visual inspection, the era of 3D measurement is coming

With the development and progress of machine vision, 3D machine vision has ushered in a huge opportunity in the automation industry. According to Grand View Research, by 2027, the global 3D machine vision market is expected to reach US$3.46 billion, with a compound annual growth rate of about 14.7%. Quality assurance and inspection applications are expected to occupy the top spot in the 3D machine vision market by 2022.

View Details 》2022-09-09

Guangdong 3D profile measuring instrument is based on CCD digital image

Guangdong 3D profile measuring instrument is based on CCD digital image, and is produced by relying on computer screen measurement technology and powerful software ability of spatial geometric calculation. After the computer is installed with a special control and graphic measurement software, it becomes a measurement brain with a software soul and is the main body of the entire device. It can quickly read the displacement value of the optical ruler, and obtain the result immediately through the operation of the software module based on spatial geometry; and generate a graph on the screen, and the operator can compare the graph, so that the possible deviation of the measurement can be visually distinguished. Guangdong 3D contour measuring instrument is a high-precision optical Guangdong 3D contour measuring instrument. It is composed of a high-precision workbench structure.

View Details 》2022-09-09

Guangdong 3D Profiler is a non-contact optical instrument

Guangdong 3D Profiler is a non-contact optical instrument with dual LED light source, which basically does not damage the sample. Select different measurement modes according to the sample. Mainly used for mutual moving interference mode (PSI) for measuring smooth surface roughness, and vertical scanning interference mode (VSI) for height, width, radius of curvature, roughness measurement, etc.

View Details 》2022-09-09

Analysis of the scale and development prospect of China's machine vision market

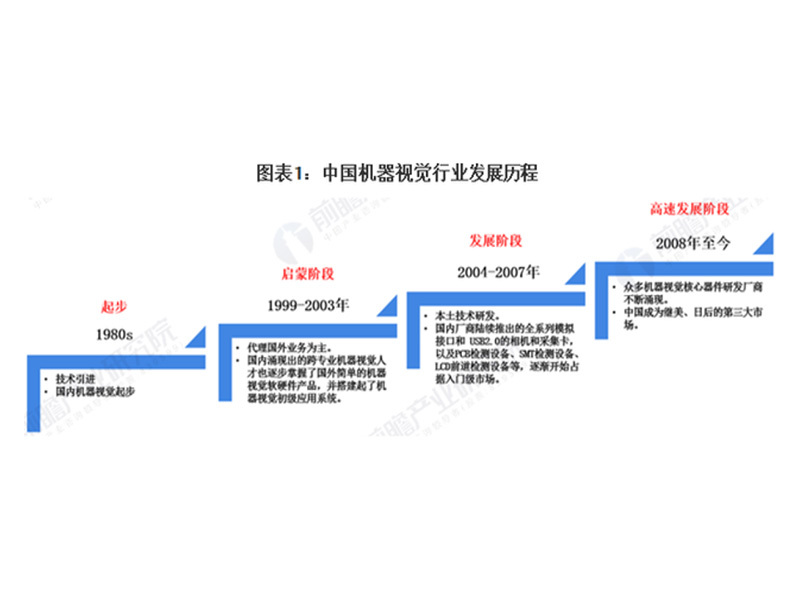

Domestic machine vision originated from the first batch of technology introductions in the 1980s. Since many electronics and semiconductor factories settled in Guangdong and Shanghai in 1998, machine vision production lines and advanced equipment have been introduced into my country, and the agents and system integrators of international machine vision manufacturers have been born. The development of machine vision in China has mainly gone through three stages. The first stage is the enlightenment stage from 1999-2003. At this stage, Chinese enterprises mainly serve customers through agency business, and guide customers to understand and recognize machine vision in the process of service, thereby opening the historical process of machine vision in China. The second stage is the development stage from 2004 to 2007. At this stage, local machine vision companies began to explore the research and development of machine vision software and hardware devices carried by more independent core technologies, and key breakthroughs were made in many application fields. The third stage is the high-speed development stage after 2008. At this stage, many R&D manufacturers of machine vision core components continued to emerge, and a large number of real system-level engineers were continuously cultivated, which promoted the high-speed and high-quality development of the domestic machine vision industry.

View Details 》2022-09-09

what? Flash meter? Where is holy?

Flash tester, many people may be hearing this name for the first time. She has many names, including intelligent automatic flash tester, flash test imager, one-button image tester, quick tester, etc. Flash tester should be regarded as a nickname. "Flash" means fast, just like lightning, it is conceivable that it is a fast measuring instrument, mainly used for two-dimensional measurement, and can be widely used in mobile phones, automobiles, precision parts, machinery, electronics, molds, connections It can be said that "where there is measurement, there is a demand for flash testers". It is especially suitable for batch measurement of small-sized workpieces such as mobile phone accessories, gears, springs, screws, etc.

View Details 》2022-09-09

3D visual inspection, the era of 3D measurement is coming

With the development and progress of machine vision, 3D machine vision has ushered in a huge opportunity in the automation industry. According to Grand View Research, by 2027, the global 3D machine vision market is expected to reach US$3.46 billion, with a compound annual growth rate of about 14.7%. Quality assurance and inspection applications are expected to occupy the top spot in the 3D machine vision market by 2022.

View Details 》