Latest News

Bomming Vision Product Center

Bomming Vision Solution

Ai Deep Learning Algorithm Platform

Lithium Battery Industry

3c Vision Positioning Guidance System

Chip Positioning Vision System

Magnetic Material Size Sorting Machine

Ai Deep Learning Algorithm Platform

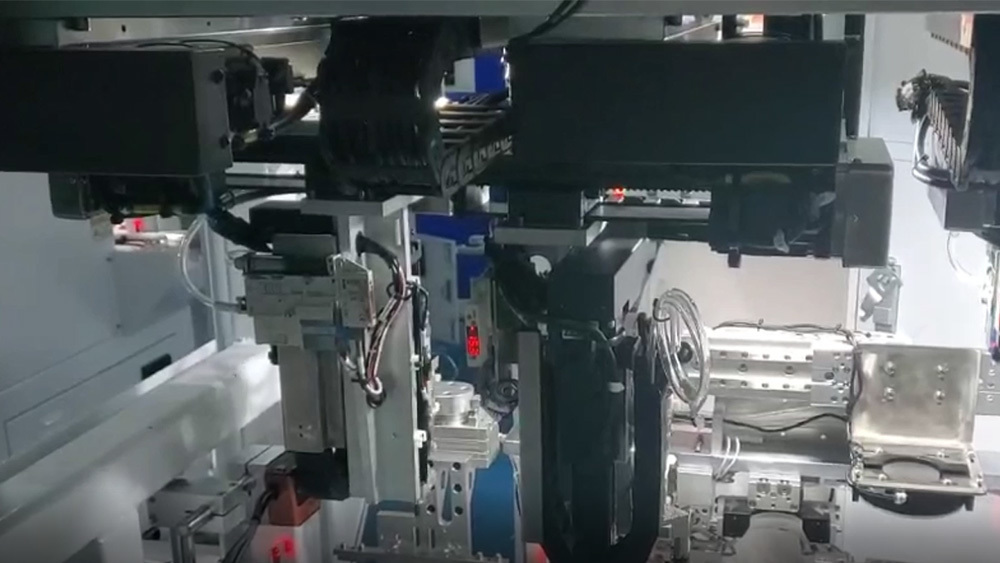

Bomming snake wave pole plate testing equipment and pole ear welding mark height testing equipment for the lithium battery industry tailored, together with well-known lithium battery enterprises, in-depth solution to the industry pain points, professional detection of lithium battery pole ear welding process after the solder joint height, and detection of lithium battery pole plate snake and wave defects, repeatability up to micron level.

More +

Lithium Battery Industry

Bomming magnetic material appearance size sorting equipment, through deep learning to enhance feature extraction, in the case of not obvious defect features, still has a strong defect detection ability. At the same time, the traditional image processing is used to extract the defect characteristics, which can be closer to the customer's customized judgment conditions, quantitative discrimination, and rapid modification of the discrimination conditions. The operation is simple and clear, one key start, the magnetic material size, missing Angle, hidden cracks, poor coating and other defects for all-round detection.

More +

Ai Deep Learning Algorithm Platform

Bomming chip positioning visual inspection equipment can detect the wafer probe, chip round hole and outer R Angle in full size to ensure that unqualified and bad chips are screened out, effectively ensuring the smooth assembly of the probe and module, module and base, and its accuracy is up to 0.7μm.

More +

Chip Positioning Vision System

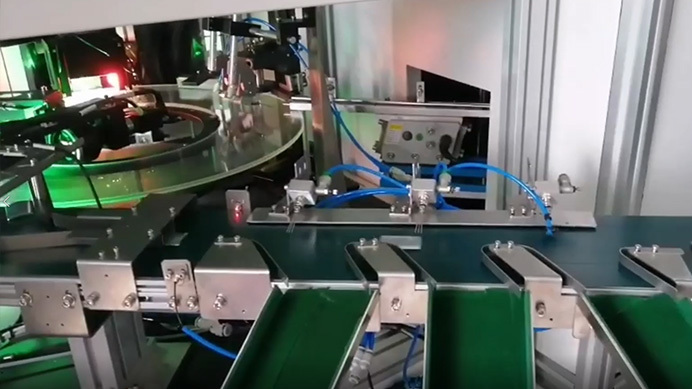

Bomming screw machine positioning system, the need to lock the product for photo analysis, identify the need to lock the screw hole position, through the visual positioning and correction function to build the relationship between the screw and the hole, guide the multi-axis robot to move to the designated coordinates, automatically complete the product lock screw work. Flexible and efficient replacement of products is possible only by modifying the points.

More +

Magnetic Material Size Sorting Machine

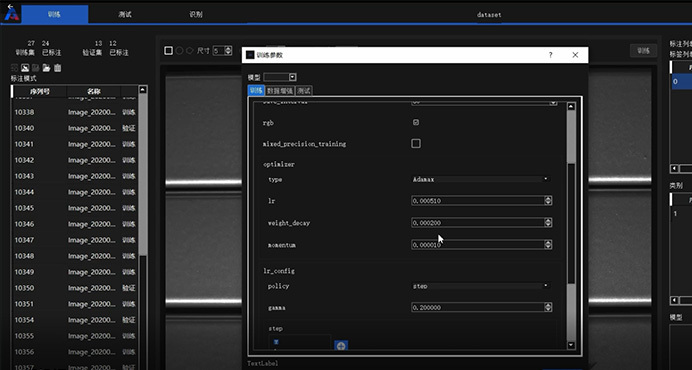

Bomming AI deep learning algorithm platform can easily control AI industrial vision inspection, generate offline packages with one click, quickly deploy to the production line, and identify quickly and accurately, which is suitable for a variety of complex appearance detection, segmentation, texture, material classification, and deformation unstable feature positioning. By visualizing the training process, real-time observation of the training process, to meet the needs of various applications in the market.

More +ABOUT US

Zhuhai Bomming Vision Technology Co., Ltd

The company was founded in September 2016, headquartered in the South Software Park of the National High-tech Zone, is a domestic high-tech enterprise, committed to the development and application of optical vision technology, to meet the requirements of online or offline measurement in the manufacturing process of different industries, the core technology management team members have more than 15 years of machine vision inspection application development experience. Good at providing diversified graphic image acquisition and processing, pattern recognition and automation solutions.

-

200

The total number of employees in the company is about 200

-

75

%Technicians account for 75%

-

30

%The proportion of doctors and masters is about 30%

Guangdong Keerda Electronics Co.,Ltd

Bomming Vision News Center

09-09

09-09