Guangdong 3D Profiler is a non-contact optical instrument

Release Time:

2022-09-09 09:03

Guangdong 3D Profiler is a non-contact optical instrument with dual LED light source, which basically does not damage the sample. Select different measurement modes according to the sample. Mainly used for mutual moving interference mode (PSI) for measuring smooth surface roughness, and vertical scanning interference mode (VSI) for height, width, radius of curvature, roughness measurement, etc.

The surface defect of steel is an important factor that determines the quality. Reducing surface defects is an effective measure to improve product quality, reduce production costs and increase economic benefits. In order to reduce surface defects in steel, timely defect detection is required in order to adjust the rolling mill in time. As an automatic online surface defect detection device, the profiler is widely used in the online detection of round steel, rebar, steel pipe, H-beam, T-beam, square steel, etc.

Guangdong 3D profile measuring instrument is a non-contact non-destructive three-shaped surface measuring instrument with convenience, excellent performance and high cost performance. The ninth generation system uses the unique dual LED illumination source ZL technology to better detect ultra-smooth and very rough surfaces. The measurement range can reach sub-nanometer roughness to millimeter step heights. Easy-to-use operating modes, fast data acquisition capabilities, powerful software features, Egyptian-grade reproducibility, and more. At the same time, the optional X-Y automatic stage makes it possible to program samples.

This instrument adopts FLCOS principle, which can realize fast confocal scanning without mechanical movement. It has the characteristics of high speed, stability and unlimited use time. Because the mechanical vibration can cause jitter during the measurement and the usage time is limited, other existing brands of confocal microscopes all use lens vibration scanning.

Features of Guangdong 3D Profiler:

1. The 3D form is lifelike, presenting the nano world.

Users can observe nanometer-level details in the field of view using a color confocal observation method.

2. The 3D scanning speed is incredible.

A full 3D scan takes less than 10 seconds. When scanning samples with low reflectivity at scan speed, 3D scan time is less than 3 seconds.

High quality objective lens with good image quality.

Compared to laser confocal microscopy, horizontal and longitudinal resolutions reach the limits of optical microscopy systems.

4. Multi-wavelength LED light source.

There are four independent LED light sources for red, green, blue and white to meet various application needs.

5. The picture quality is amazing.

The display resolution reaches 2560×1440 pixels, using a 1360×1024 high-resolution CCCD. Images are sharp, vivid, and lag-free.

6. Sequential lighting of color images.

In red, green, red, green and blue LEDs alternately illuminate and restore the three color images to a high-resolution color image. Compared with other brands, it adopts pixel interpolation algorithm, which has better color protection and restoration performance.

Latest News

2022-09-09

3D visual inspection, the era of 3D measurement is coming

With the development and progress of machine vision

View Details 》2022-09-09

Guangdong 3D profile measuring instrument is based on CCD digital image

Guangdong 3D profile measuring instrument is based on CCD digital image

View Details 》2022-09-09

Guangdong 3D Profiler is a non-contact optical instrument

Guangdong 3D Profiler is a non-contact optical instrument with dual LED light source

View Details 》2022-09-09

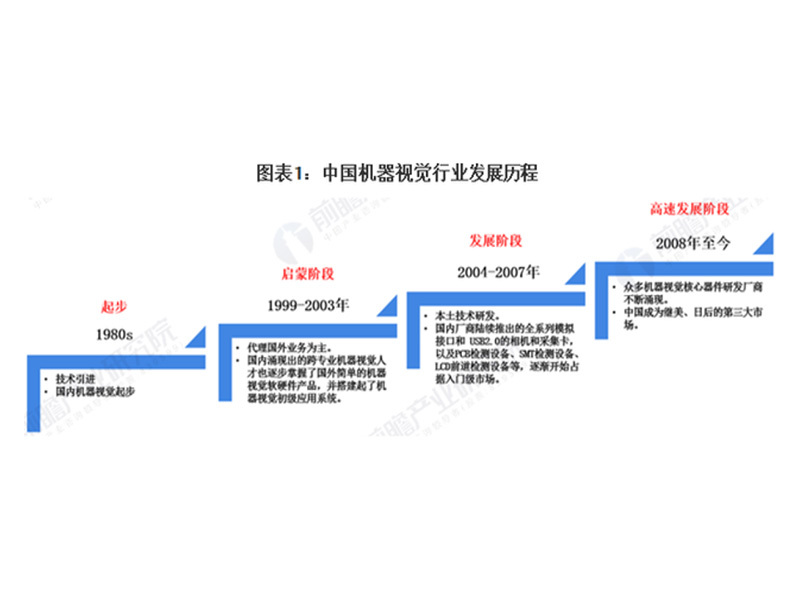

Analysis of the scale and development prospect of China's machine vision market

Domestic machine vision originated from the first batch of technology introductions in the 1980s.

View Details 》2022-09-09

what? Flash meter? Where is holy?

Flash tester, many people may be hearing this name for the first time.

View Details 》2022-09-09

3D visual inspection, the era of 3D measurement is coming

With the development and progress of machine vision, 3D machine vision has ushered in a huge opportunity in the automation industry.

View Details 》